We start by understanding your goals, users, operational context, and existing systems. Through collaborative workshops and conversations, we identify high value use cases, define clear success metrics, and establish a practical roadmap aligned to your business priorities.

IMMERSIVE TRAINING & DIGITAL OPERATIONS FOR MANUFACTURING

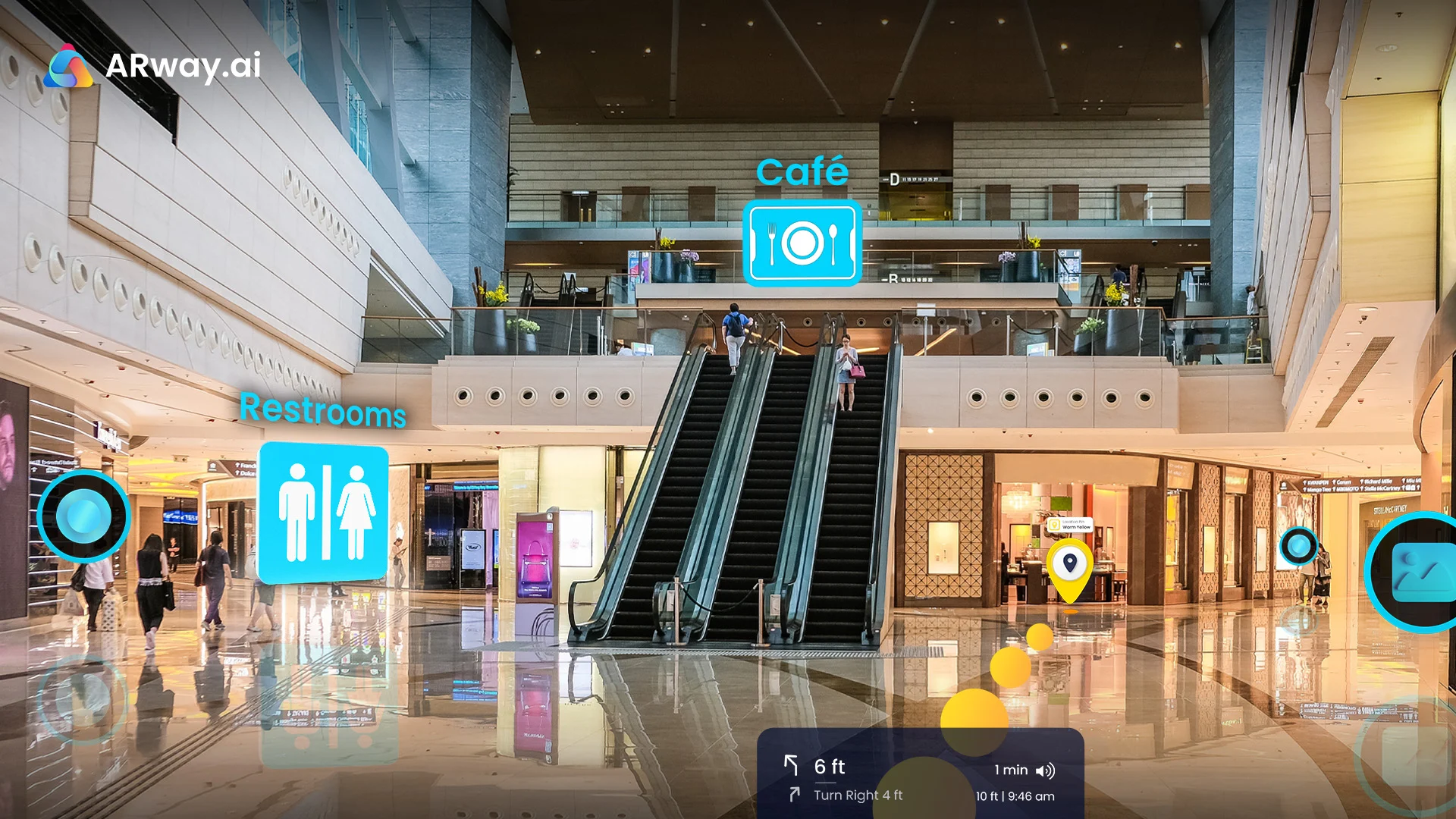

We help manufacturers modernise the factory floor. From assembly lines to advanced production cells, our XR, 3D Web, and AI solutions enable teams to visualise workflows, train operators, and optimise processes with greater clarity and control.