We start by understanding your goals, users, operational context, and existing systems. Through collaborative workshops and conversations, we identify high value use cases, define clear success metrics, and establish a practical roadmap aligned to your business priorities.

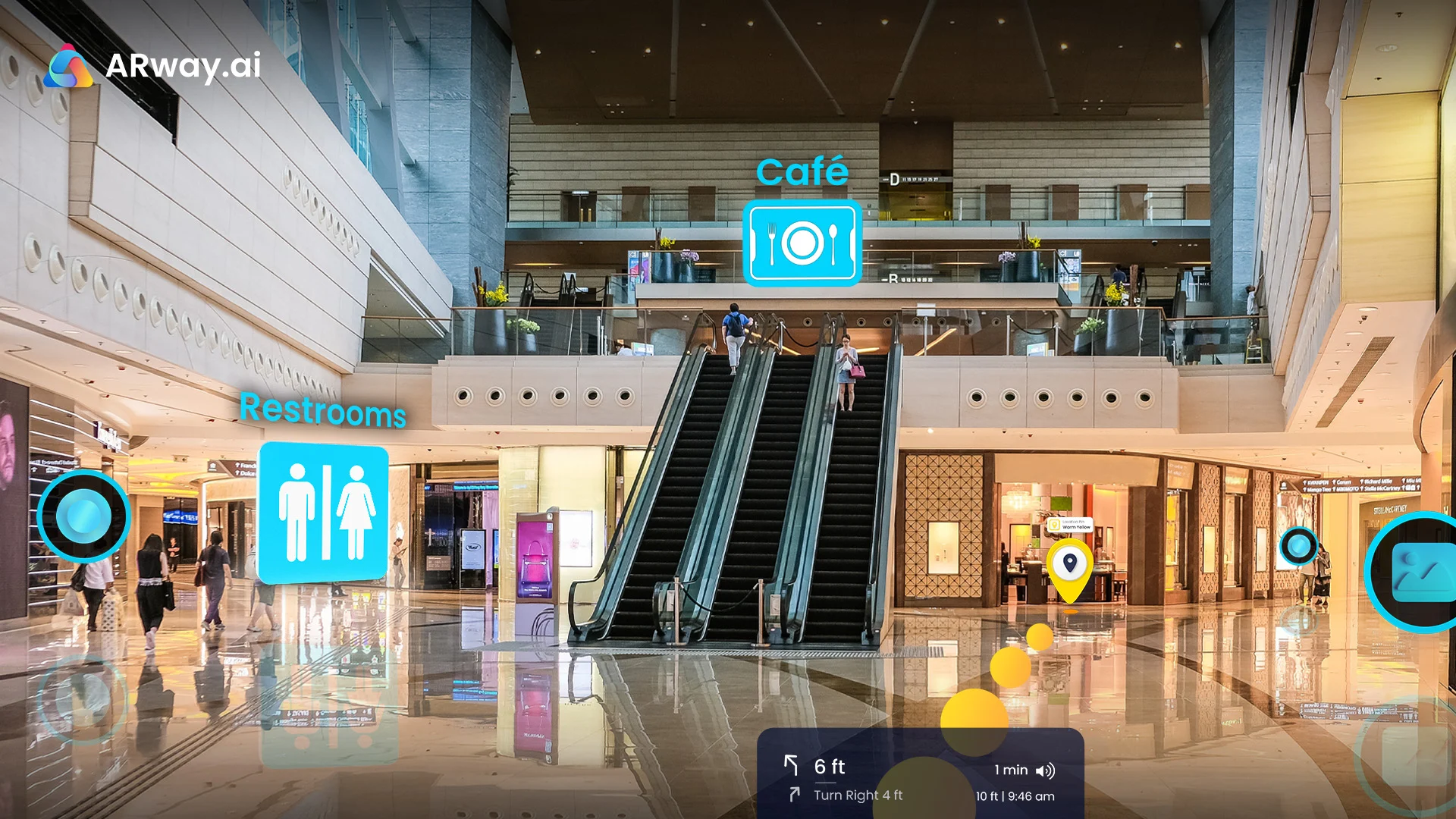

AUGMENTED AND VIRTUAL REALITY FOR LOGISTICS & SUPPLY CHAIN

We build immersive tools for logistics, warehousing, and supply chain to train teams, visualize fleets, and streamline decision-making.